Menu

BioF-IV High-Throughput Plant Bioreactor

Product Structure and Components

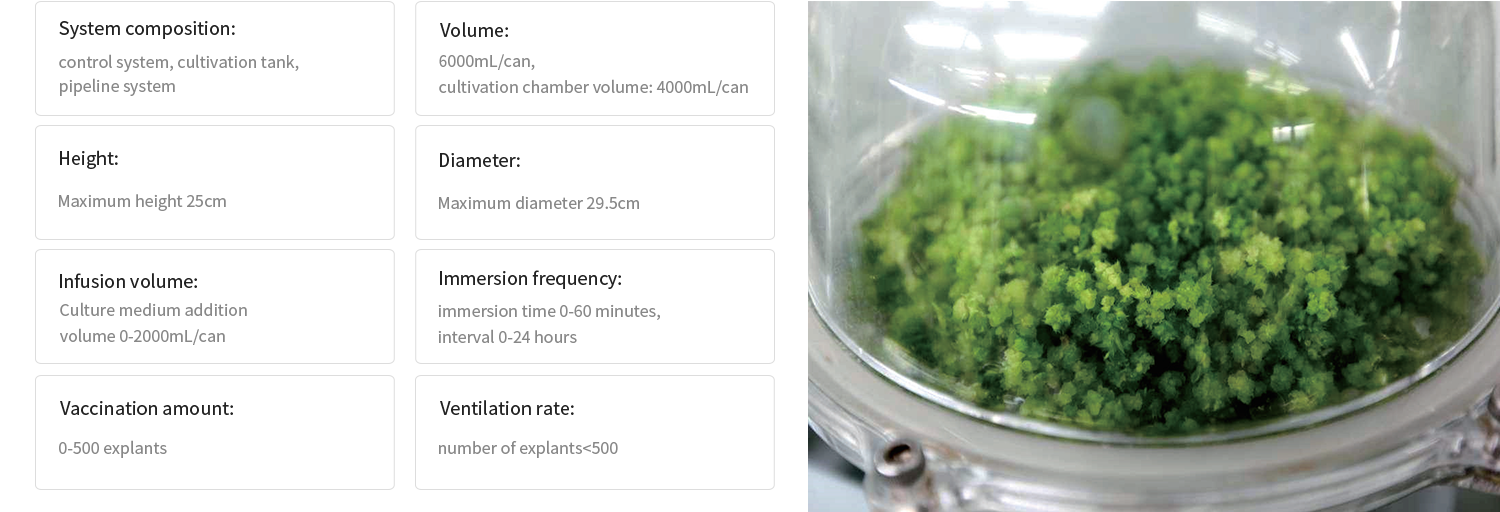

High-Throughput Plant Bioreactor Composition:The bioreactor is composed of tank assemblies, series/parallel connection components, gas exchange and power control units, and inoculation accessories.

Enhanced Cultivation Capacity:By configuring the reactor tanks in series or parallel, the cultivation capacity of the plant bioreactor can be significantly increased, allowing for higher processing throughput.

Integrated Design: The system features a holistic design with complete supporting components, ensuring ease of operation, effective contamination prevention, and improved inoculation efficiency.

Product Advantages

High Throughput: Dozens or even hundreds of plantlets can be cultivated within a single reactor vessel, significantly increasing the quantity compared to traditional tissue culture bottles.

Simplified Process: The entire life cycle or extended cultivation can be achieved without the need for multiple transfers, without affecting tissue development or plant growth.

High Efficiency: Timely exchange of culture medium and gas ensures the supply of nutrients and CO2, enhancing growth efficiency.

Cost Reduction: Saves a significant amount of materials, simplifies the inoculation process, and improves automation levels, thereby reducing labor costs.

High Quality: Intermittent immersion cultivation reduces vitrification, resulting in high-quality seedlings and somatic embryos with high transplantation survival rates.

Wide Applications: Suitable for plant virus elimination, seedling propagation, breeding research, bioproduction, germplasm resource conservation, genetic transformation, and other fields.

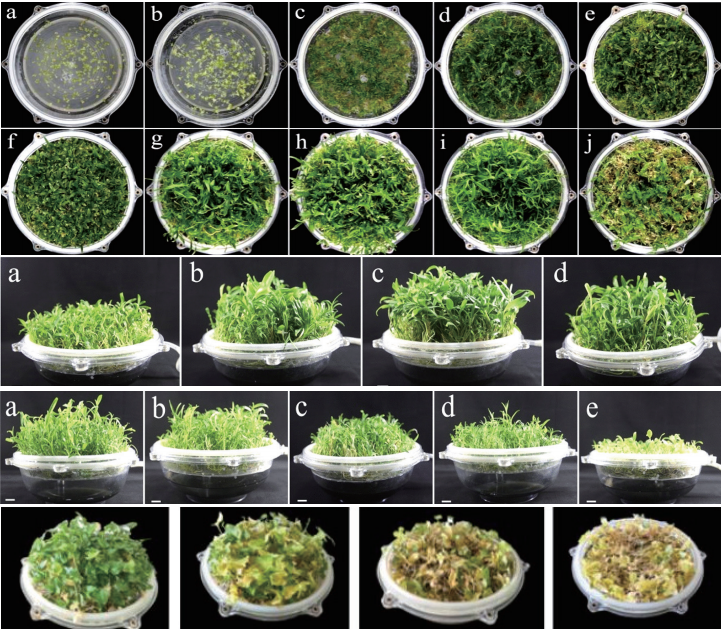

Large-Scale Cultivation

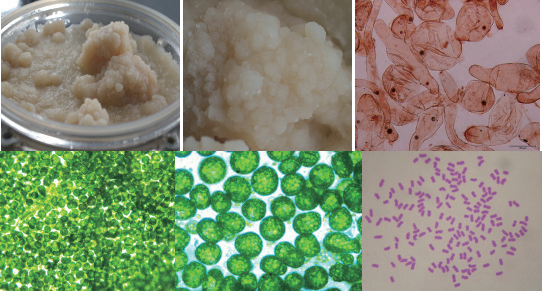

Large-Scale Cultivation Storage Organs

Storage Organs Seedling Development

Seedling Development

101, Thomson Road #28-03A United Square Singapore 307591

Delftweg 50, 2289 AL Rijswijk, The Netherlands

Hammerbrookstrasse 93,20097 Hamburg

8th Floor, Building 2, East China Normal University Science and Technology Park, 1038 Jinshajiang Road, Shanghai

Copyright ©2024 Zealquest Asia